![]()

ROGERS RAMMED EARTH

![]()

Rammed Earth Techniques

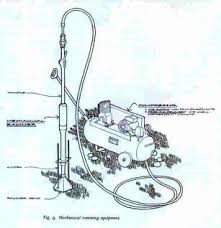

Compressor-driven Tamper

|

The compressor driven tamper shown

above is the usual contemporary tamping

device, but needs a bigger compressor.

Compressor air supply to mechanical tamper

must be a minimum 32KG. (70 LBS.) a minute.

The tamper takes a considerable concentration

to maneuver while it jumps

on your toes :-(

HAND tamping gives the BEST COMPACTION which is the CRUX of a lasting building!

![]()

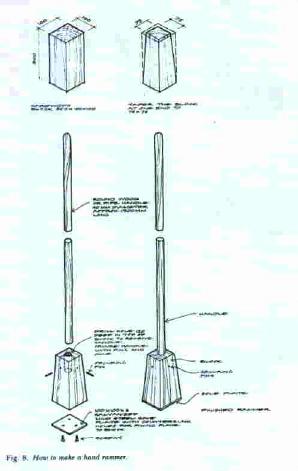

Hand Ramming Tamper

|

The alternative HAND tamping device

is easy to make and of course has no capital

outlay like its counterpart above.

The hand tamper should be at least five kilos

in weight (12 LBS) to give the "punch"

necessary to compact damp earth.

The base is made of heavy hardwood

300mm.x100mm. (12x4 inches).

The handle was not made of wood as in the

diagram above, but from a 1.5 metre length of

galvanised steel water pipe

about 30mm. diameter which gave a useful

heavier weight to the tamper.

I used this style

of hand tamper to build my house.

The steel

plate at the base (working face) is a very

necessary addition to

minimise any adherence of damp earth.

(see photo of my tamper on home page)

![]()

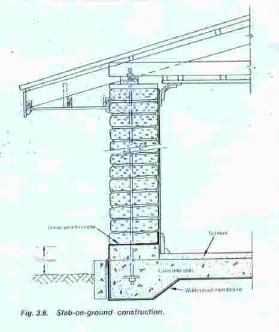

Rammed Earth Concrete Foundation detail

|

A cross-section

of slab-on-ground construction. Damp course is

laid on the slab before earth walls are begun.

Notice the continuous rio-rod extending from the

footing of concrete slab and reaching through

the earth wall to the roof plate.

This makes for a very secure roof especially in

high or cyclonic wind.

![]()

Form End Shutter or Key-Way

End Shutter or Key-Way is necessary to join on the adjoining earth section/form.

This gives strength and bonding to the walls overall length.

Imperative that the tamper foot fits both the negative & positive.

The wood stud down centre of back board has a slight chamfer

down each side to facilitate removal at tamping completion.

This shutter is 45cm wide for walls the same width.

![]()

Pouring Earth into Forms before Tamping.

When pouring loose earth into the forms prior

to tamping, make sure to pour along the form sides

NOT down the middle.

If earth is poured down

the middle forming a hill, the small gravel,

stones & clay

lumps will roll to the exterior face of your wall.

Lumps will visually be unsightly &

not homogeneous to overall wall.

![]()

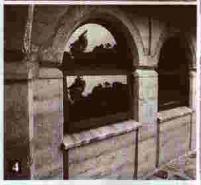

Window Lintels

|

Several methods

can be used to fill in areas above windows or

doorways.

Above is a unique method of incorporating arched

concrete lintels by Ramtec (see links).

I used heavy hardwood beams and also concrete

lintels with a brick facade to span the window

& door areas.

Contempory/commercial RE is made up of 'stone

henge panels' & is a cost cutting compromise

of simply filling in with windows & doors up

to the roof plate.

![]()

Above you can download a R.E.paper delivered in Western Australia by Stephen Dobson a Committee Member of the:

Joint Technical Committee of Standards Association of Australia and Standards New Zealand

for preparation of a Standard for Earth Building for Australia and New Zealand.

![]()

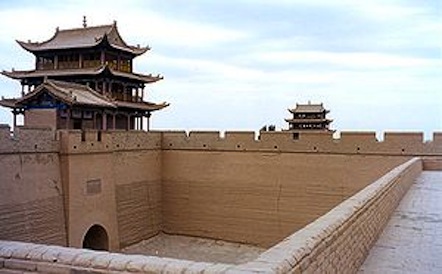

Rammed

Earth

- Great Wall China

Please ask first!